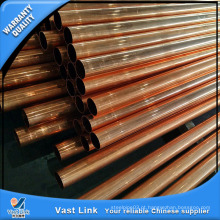

Tubos de aço galvanizado imerso a quente

Informação básica

Modelo: ASTM A53, BS1387, EN10025, GB/T3091, ASTM A500

Descrição do produto

Modelo no .: ASTM A53, BS1387, EN10025, GB / T3091, ASTM A500 Técnica: ERW Tratamento de superfície: Seção galvanizada Forma: Redonda Preços: Estoque competitivo Capacidade: 1000tons Especificação: BS Código HS: 73066100 Tipo: Material soldado: Aço carbono Uso : Transporte de dutos, Finalidades especiais, Indústria de máquinas, Indústria química, Mineração WT: 1 mm ~ 12 mm: OD: 20 mm ~ 406 mm Tempo de entrega: Muito rápido Marca registrada: VAST LINK Origem: China Tubos de aço galvanizado mergulhado a quente \ nModelo NO: Q195, Q235, Q235B \ nTipo: Soldado \ nUso: Tubo, Finalidade Especial \ nEspessura da Parede: Espessura e Fina \ nTipo de aço: Série 300 \ nLiga ou não: Não liga \ nForma da seção: Redondo \ nMercados de exportação: Global \ nInformações adicionais. \ nMarca comercial: VAST LINK \ nEmbalagem: Navegável \ nPadrão: BS \ nOrigem: China \ nCódigo HS: 73066100 \ nCapacidade de produção: 50.000mt / Y \ nPrazo de execução: 15-20 dias após seus depósitos \ nPagamento: 30% depósitos por TT em avanço. \ nAplicação Transporte de água, óleo e gás. Prédio. Estrutura do tubo \ n \ nCertificado ISO9001-2008, avaliação BV, Soncap, QC, \ n \ nTratamento de superfície roscado e acoplamentos, tampa de plástico azul, faixa azul \ n \ nInformações básicas. \ NModelo NO: TYT2010311FRK \ nTipo: Soldado \ nUsage : Tubo \ nEspessura da parede: Espessura \ nTipo de aço: Série 400 \ nLiga ou não: Não liga \ nForma da seção: Redondo \ nTécnica: ERW \ nAplicação: Tubo de estrutura \ nTubo especial: Tubo de parede espessa \ nCertificação: API, BSI \ nPadrão : ASTM A 53 \ nOrigem: China \ nCódigo HS: 73065000 \ nCapacidade de produção: 60.000 toneladas / ano \ nDescrição do produto \ nCommodity: Tubo de aço galvanizado \ nRecursos: \ n-2008 \ nAmbas as extremidades parafusadas, uma extremidade é o acoplamento a outra extremidade é a tampa de plástico. \ n5. Tubo de aço: \ nA) Tubo de aço GTC (roscado galvanizado e acoplamento): DN15-DN250 (NB3 / 8 '' - NB10 '') \ nB) Tubo de aço GPE (extremidade plana galvanizada): DN10-DN200 \ nC) Aço ranhurado tubo: DN15-DN200 (NB 1/2 '' - NB8 '') \ nD) Usado para fornecimento de líquido de baixa pressão, como água, gás e óleo \ nE) O produto se aplica a vários tubos anticorrosivos \ n6. Embalagem: em pacotes \ nProcuramos ouvir de você!

| Table of Comparison between Fushunda Steel Standard and International Standard | |||||||

| National Standard | Enterprise Standard | Comparison Results | |||||

| Welded Steel Pipe for Transportation of Low Pressure Fluid | Welded Pipe | ||||||

| GB/T 3091-2008 | Q/FSD 01-2002 | ||||||

| 1 | Outside Diameter of Steel Pipe | Outside Diameter of Steel Pipe, Tolerance of Outside Diameter | Better than National Standards | ||||

| Outside Diameter D/mm | Tolerance of Pipe Outside Diameter | Tolerance of Pipe End Outside Diameter/mm | Outside Diameter D | 8" | ±0.60mm | ||

| D≤48.3 | ±0.5mm | 5"-6" | ±0.50mm | ||||

48.3| ±1.0% | 4" | ±0.40mm | | ||||

168.3| ±0.75% | -0.8~+2.4 | 3"-2 1/2" | ±0.30mm | | |||

| D>508 | ±1.0% | -0.8~+3.0 | D≤2" | ±0.20mm | |||

| Tolerance of W.T. | 10% | Wall Thickness | 1.8-5.75mm | 5% | |||

| 2 | Length | Usual Length | Tolerance | Length | Usual Length | Tolerance | Better than National Standards |

| 4m-12m | -0~+20 | D≤2" | -0~+5 | ||||

| 2 1/2"≤D≤4" | -0~+10 | ||||||

| Multiple length: 5-10mm tolerance for each multiple length | -0~+20 | 5"≤D | -0~+15 | ||||

| Stecial Length | -0~+20 | ||||||

| 3 | Bending | Φ≤114.3mm | Straight for ordinary use or negotiate the bending | Bending | ≤1.5 | Better than National Standards | |

| Φ≤114.3mm | Smaller than 0.2% of full steel pipe | ||||||

| 4 | Pipe End | The two end faces of steel pipe should be vertical with axes of the steel pipe. No burr in the incising | Pipe End | The two end faces of steel pipe should be vertical with axes of the steel pipe. No burr in the incising | Equal to National Standards | ||

| ≥Φ114.3mm | Cutting tilt: no more than 3mm | ≥Φ114.3mm | Cutting tilt: no more than 3mm | ||||

| 5 | Weight | Ungalvanized steel pipe could be delivered according to its actual weight or theoretical weight. Galvanized steel pipe could also be delivered according to its actual weight or theoretical weight. Computation of the weight according to theoretical weight equation, and referring to the factor table of galvanized pipe. | Weight | Ungalvanized steel pipe could be delivered according to its actual weight or theoretical weight. Galvanized steel pipe could also be delivered according to its actual weight or theoretical weight. Computation of the weight according to theoretical weight equation, and referring to the factor table of galvanized pipe. | Equal to National Standards | ||

| 6 | Chemical Composition | Execute according to GB/T223, GB/T4336, GB/T2006 and GB/T20123 | Chemical Composition | Execute according to GB/T222, GB/T223, GB/T699, GB/T700, GB/T1591 and GB/T4336 | Better than National Standards | ||

| 7 | Mechanical Properties | Execute according to GB/T228, GB/T2795, GB/T244 and GB/T246 | Mechanical Properties | Execute according to GB/T228, GB/T2795, GB/T244 and GB/T246 | Equal to National Standards | ||

| 8 | Surface Quality of Steel Pipe | Internal and external surface of pipe should be slick. Folding crack, delamination and lap weld are not permitted. Other defects that no more than the negative deviance of wall thickness are permitted. Internal burr is allowed to exist. Steel pipe with >100mm, could be repaired for its defects and carry out water pressure experiment. Galvanized steel pipe should carry out homogenization experiment for its galvanization layer. Steel pipe sample should not turn red after 5 times of consecutive immersing in cupric sulfate solution (color of copper plating). There should be complete galvanized layer on both the internal and external surface of the pipe, and should not have the black spot and bubble that characterized the ungalvaniztion. Little coarse surface and existence of sectional zinc hump are allowed. | Surface Quality of Steel Pipe | Steel pipe should not have defects such as crack, scar, folding, delamination, and lap weld etc. pull line, scoring, weld seam dislocation, scuffing not larger than the negative deviance of wall thickness and the trace of elimination skin of ferric oxide and burr are allowed. Internal burr is allowed to exist. Galvanized steel pipe should carry out homogenization experiment for its galvanization layer. Steel pipe sample should not turn red after 5 times of consecutive immersing in cupric sulfate solution (color of copper plating). There should be complete galvanized layer on both the internal and external surface of the pipe, and should not have the black spot and bubble that characterized the ungalvaniztion. Little coarse surface and existence of sectional zinc hump are allowed. | Better than National Standards | ||

Grupo de Produto : Tubos e tubos de aço galvanizado

Premium Related Products

outros produtos

produtos quentes

Novos produtos inovadores de aço carbono tubo quadradoAlto grau de grossista agendamento de 80 tubos de aço carbonoAlibaba expressa preço de fábrica por atacado preto aço carbono erw pipeNovos produtos inovadores tubo de aço galvanizadoFornecedores grossistas chineses galvanizado tubo de aço sem costura para material de construção e oleodutoFabricante de alta precisão fabricante do tubo de aço sem costura de 34mm no alibabaBoas especificações materiais de tubo de aço inoxidável / tubo de aço inoxidável feito na ChinaBobina de aço galvanizado revestida de corLista de preços de tubulação de aço de baixo carbono da melhor qualidadeAlibaba Melhor Fornecedor, ASTM A615, GB1449, BS4449 barras de aço deformadasTubo de aço de resistência à compressão em estoqueTubo tubo de aço sem costura / tubo de aço 8 distribuidorTubo de aço de grande diâmetroPreço da tubulação de água de açoTubo de aço galvanizado sem costura DIN2391 EM STOCKJBC tubo de aço preto, melhor tubo de aço frio extraído